Our Services

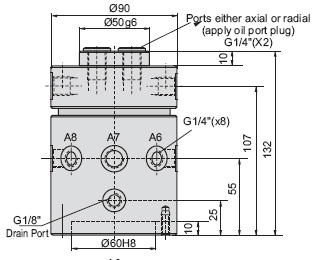

Hydraulic Rotary Valve Single Double Acting

IMPORTANT

- The oil must be clean use 25 mfiltration.

- Mounting of the Rotary Valve should be coaxial with respect to rotary table. The top support strip used for rotation prevention of the central rotor should have a float so that side forces/side loading are not generated.

DESCRIPTION

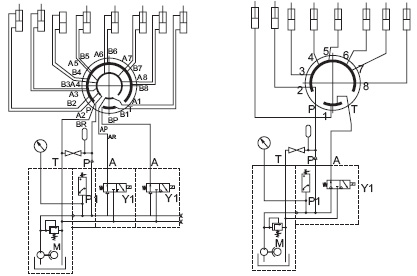

Rotary Valves are used on continuous rotary and indexing table for a sequential clamping and declamping operation, on a number of fixtures that are mounted on the Rotary Table. These Valves are generally meant to work at low rotating speeds upto 3 to 5 RPM. These Rotary valves helps the component loading /unloading and clamping / de-clamping on Rotary Table - at loading station- manually, when rest of the stations are engaged for machining. De-clamping takes place at the loading station only. These rotary valves can be used in single/double acting applications. Clamping/ de-clamping circuitary can be interlocked with Machine tool operations, with regard to work table forward / retract operations.

FEATURES

- Max. Operating pressure 200 bar.

- Can be used for single/double acting applications.

- Nominal Bore Nb5.

NOTE

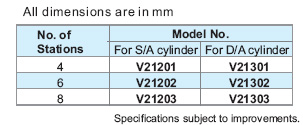

- Model No V 21201 to V 21203 is for Single Acting Cyl.

- Model No V 21301 to V 21303 is for Double Acting Cyl.

- Custom built special rotary valves can also be supplied.

- Ordering specification for seal kit. Add prefix "SK" to the model Number.

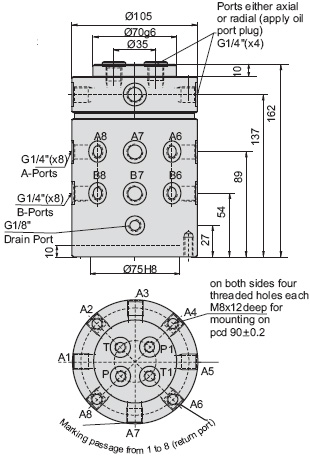

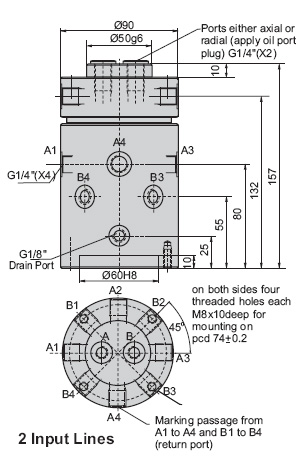

Rotary Distributor Hydraulic Nb5

IMPORTANT

- The oil must be clean use 25 mfiltration.

- Mounting of the Rotary Valve should be coaxial with respect to rotary table. The top support strip used for rotation prevention of the central rotor should have a float so that side forces/side loading are not generated.

DESCRIPTION

Rotary distributor supplies the pressure oil to rotating & swiveling installation. These are used when one or more fixtures or elements have to be supplied with Hydraulic Power on the jigs mounted on Rotary tables. Rotary distributor will have one input & several outputs - like 1x4,6 or 8 outputs or 2 inputs & 2 x 4,6 or 8 outputs - or 4/6 inputs & multiples of 4/6 x 4/6, or 8 outputs. These distributors are designed to work at pressures upto 250 bar & at small rotary speeds of 3 to 5 RPM, flow not to exceed 4 ltrs/min. Input lines are connected via external valving to pressure lines, return lines or even pneumatic pressure lines. Thus the external valves control the Hydraulic clamping elements on the jig either to clamp the work piece or de-clamp the work piece. The unutilised ports are to be plugged. Rotary distributor is generally mounted above the rotary table using suitable support at the center of gyration of the installation. In special designs of Rotary table, if the table permits, the rotary distributor can be mounted below the table.

FEATURES

- Max. Operating pressure 200 bar.

- Can be used for single/double acting applications.

- Nominal Bore Nb5.

NOTE

- Special Designs with ports reconfigured to suit Customer requirements also can be designed, developed and supplied.

- Ordering specification for seal kit. Add prefix "SK" to the model Number.

98111-82148