Our Services

Tube Couplings

To connect pressure or vacuum lines to plain tubes & pipes. The coupling is simply pushed over the end of the tube & pressed firmly to the stop position. This provides an effective leak-proof sealing. The tube can be disconnected merely by pressing down the lever & pulling off the coupling. No welding, threading or flaring of tubes.

Advantages Over Permanent Connections:

- Greater safety by automatic shut off

- Minimizes down time

- Permits rapid change over

- Reduces time for connection

- Speeds line change over

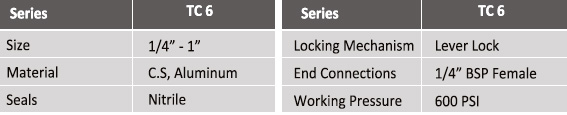

Selection of Quick Disconnect Couplings:

- Function or Need

- Pressure Requirement

- Type of Coupling

- Seal

- Flow Characteristics

- Material

- Pipe and Thread Size

For Best Performance of the Couplings :

- Use only with the recommended media

- Be sure to choose the appropriate type sealing materials for your application

- Keep the Couplings always clean & free of dust by installing suitable dust caps / dust plugs

- Use a filter for fluid & air as foreign materials may damage the couplers

- Be sure that the thread tape scraps do not enter the line.

- Do not over tighten the fittings as the threads may be damaged

Warnings :

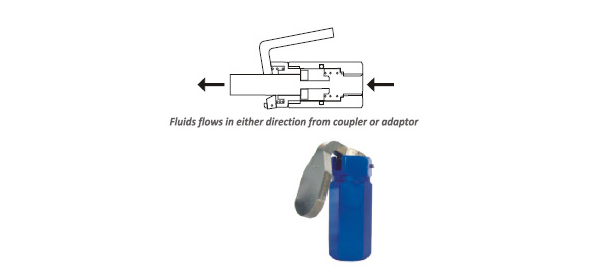

- Media must flow from the couplers to the adopters

- Do not connect or disconnect the couplers when pressurized

- Do not apply palliative pressure to coupler when it is disconnected

98111-82148