Our Services

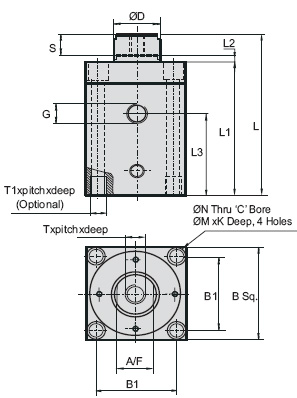

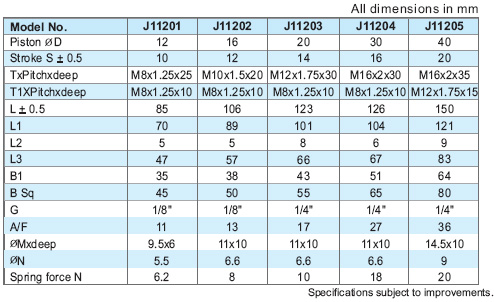

Hydraulic Support Jack Single Acting Sleeve Type

IMPORTANT

- Support force should be greater than Clamping force.

- Support force should be at least 150% of Clamping force.

- Do not apply eccentric Load. Clamping force must be directly over the support point.

- If there is a risk of cutting coolants being sucked via air vents the same to be avoided by connecting air vent. The other end of which is placed in a safer position.

DESCRIPTION

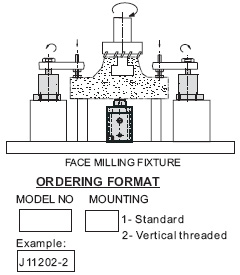

Hydraulic Work Support Jacks are used to provide self adjusting rest for the work piece during machining operations. They compensate for work piece surface irregularities, deflection and vibration under machining loads.Work piece is supported by the plunger under the spring force. When system pressure is applied the plunger locks hydraulically providing a rigid support to the workpiece.

FEATURES

- Min/ Max Operating Pressure 50 / 250 bar.

- Bottom threaded mounting holes are available as optional.

NOTE

- Refer general design notes before selection & use.

- Spring should not be used to lift the work pieces.

- Ordering specification for seal kit. Add prefix "SK" to the model Number.

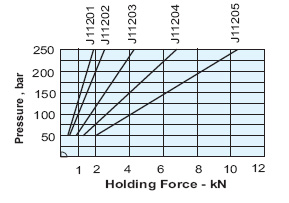

GRAPH

- Admissible Holding force ‘F’ as a function of operating pressure ‘P”.

98111-82148